-

Tel : +86 18148038996

-

Email : zhangwenying@yankong.com

Tel : +86 18148038996

Email : zhangwenying@yankong.com

Brand:

YakoItem no.:

MS-S3Payment:

100% T/T payment before deliveryProduct origin:

Made in ChinaLead Time:

Normally 7 workdays

MS-S3 Promotional Yako 2 Phase Servo Stepper Drive

Using the latest special motor control dual-core DSP chip and the application type vector closed-loop control algorithm, thus overcoming the lose step problems of the open-loop stepper motor, at the same time, it can obviously improve motor high speed performance, reduce the degree of fever and the high school low speed vibration of motor, so as to improve the processing speed of the machine and precision and reduce the energy consumption of the machine. In addition, when the motor is continuously overloaded, the driver will output an alarm signal, with the same reliability as the AC servo system.

Features:

Application:

Application: suitable for a variety of automation equipment and instruments with great torque requirements, such as robots, industrial mechanical arms, engraving machines, stripping machines, marking machines, cutting machines, plotters, CNC machine tools, automatic assembly equipment, flower prototypes, etc.

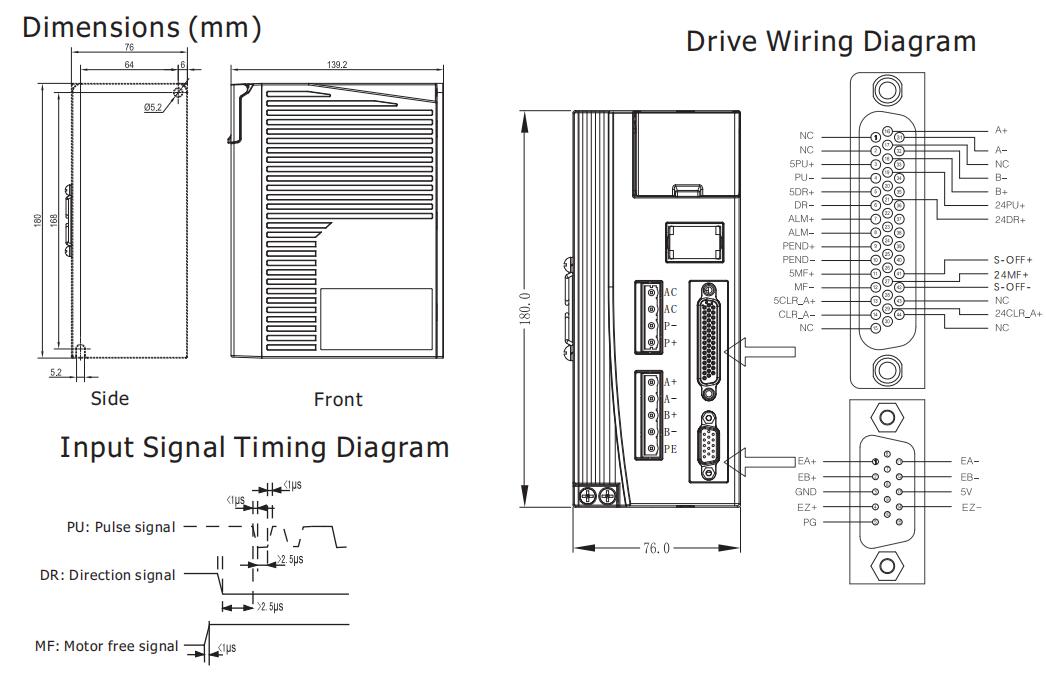

Dimensions

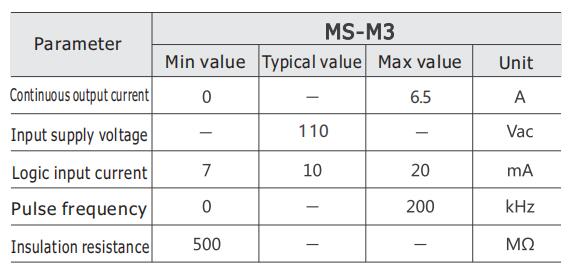

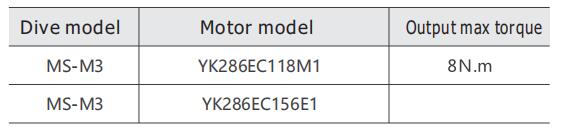

MS-S3 Electrical Index

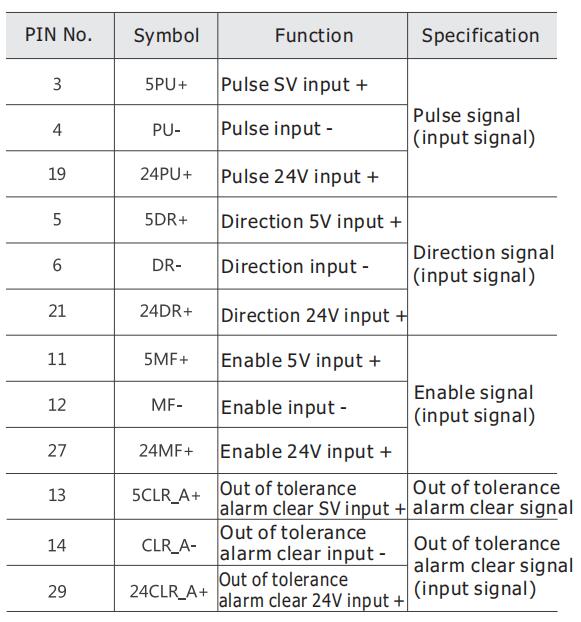

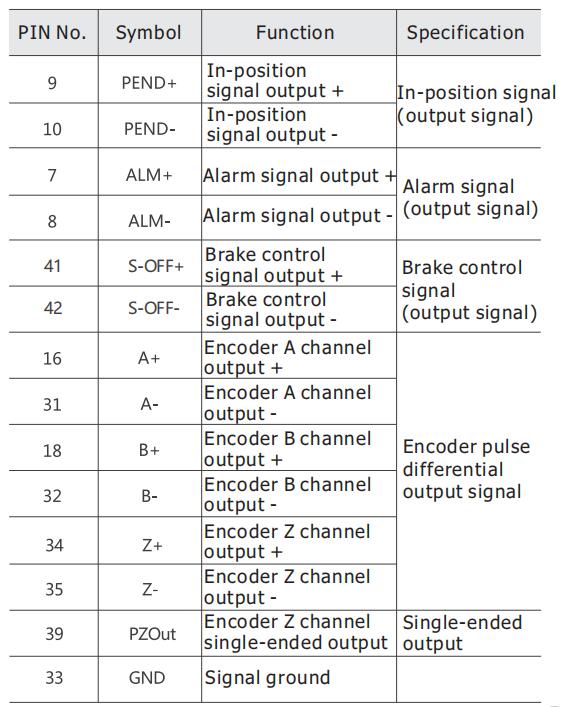

MS-S3 Terminal Definition

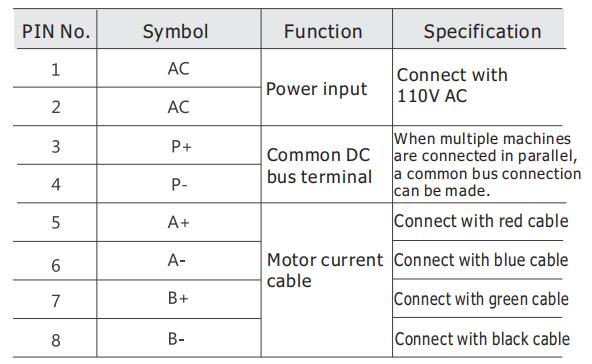

Power and Motor Input Terminals

The encoder cable is included, please connect the encoder extension cable directly to the motor encoder and drive, no

customer wiring is required.

MS-M3 has a six-digit digital tube to display the status. When the drive fails, it will stop and prompt the corresponding fault code; when multiple faults occur at the same time, these fault codes are alternately displayed. The drive will save the latest faults in the

EEPROM of the drive in the form of a queue, and the drive will save up to 10 recent historical faults.