-

Tel : +86 18148038996

-

Email : zhangwenying@yankong.com

Tel : +86 18148038996

Email : zhangwenying@yankong.com

Brand:

YakoItem no.:

SSD2505MPayment:

100% T/T payment before deliveryProduct origin:

Made in ChinaProduct weight:

0.3kgLead Time:

Normally 7 workdays

High performance SSD2505M Yako 2 Phase Close-Loop Stepper Drive

With servo-similar control circuit and superior software algorithm, YAKO Close-Loop Stepper Driver has superior performance in smoothness, noise and vibration. Smooth and accurate current control technology greatly reduces motor heat.

Features:

Application:

Application: Mainly used in engraving machines, special industrial sewing machines, wire stripping machines, marking machines, cutting machines, laser phototypesetting, plotters, CNC machine tools and other automation equipment and instruments.

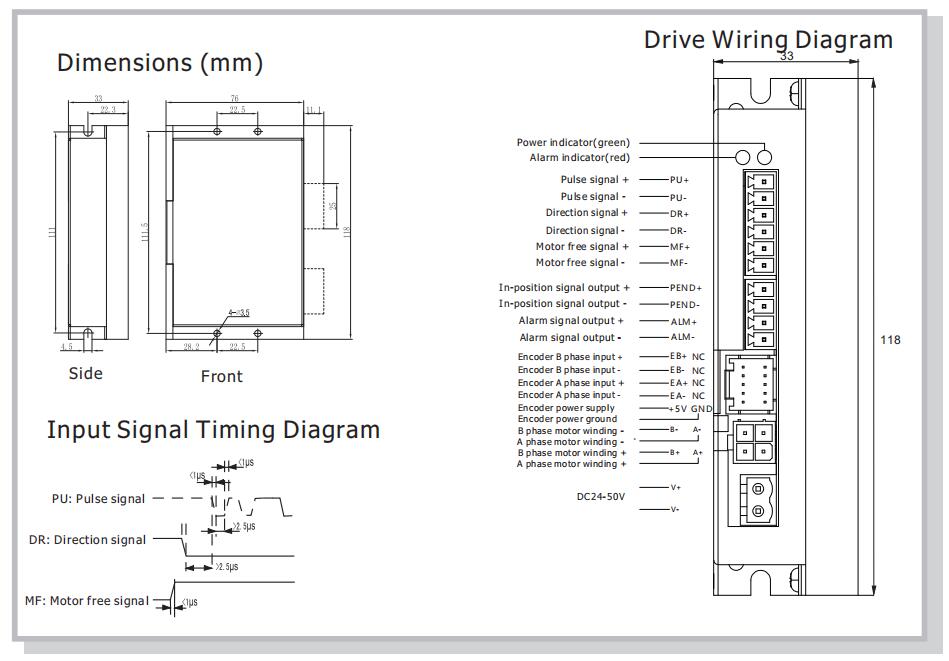

Dimensions

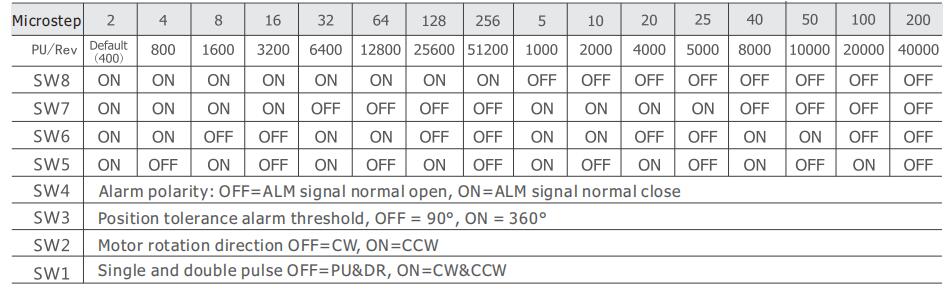

SSD2505M Microstep Setting

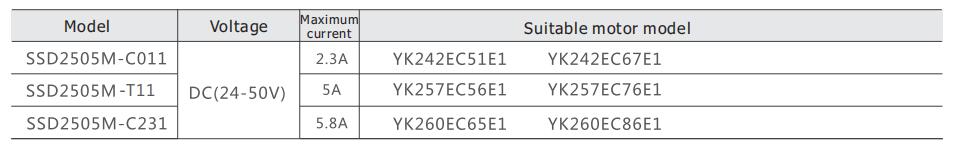

SSD2505M Terminal Introduction

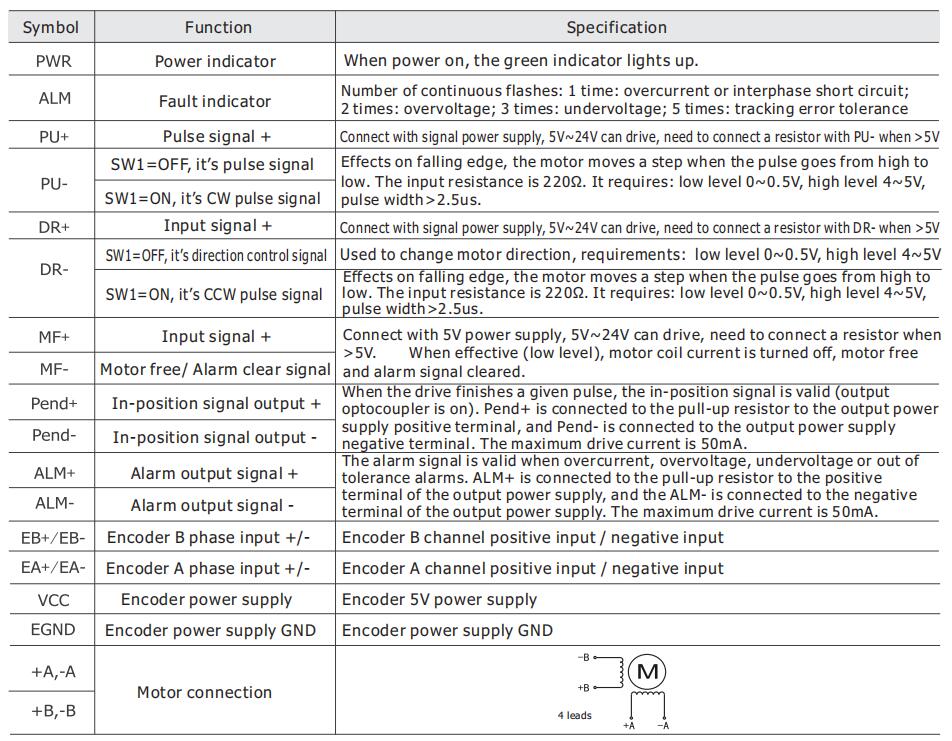

Notice:

1. Please ensure that the motor and encoder are wired correctly, otherwise the motor will be out of

tolerance after receiving the pulse.

2. The input control signal level is 5V. The current limiting resistor needs to be connected when>5V.

3. When installing the motor, it is strictly forbidden to strike the back cover of the motor to avoid damage

to the encoder.